Winckelmans – Authentic French Porcelain Mosaic

Discover the exceptional quality of Winckelmans porcelain stoneware mosaic , produced in northern France since 1867. As the last European manufacturer of unglazed, fully vitrified ceramic mosaic, Winckelmans combines 150 years of craftsmanship with modern precision technology. These tiles are characterized by their extreme density, through-the-wall coloration, and near-zero porosity—the perfect material for heavy commercial floors, historical restorations, wet areas, and architectural applications where durability and authenticity are essential.

The History of Winckelmans

The history of Winckelmans is closely linked to the late 19th-century architectural revival in France. The company was originally founded in 1867 in northern France, specializing in stoneware. The crucial step towards the production of unglazed tiles was taken by Théophile Winckelmans , who opened his factory in Lomme, near Lille, in 1894. From the outset, the goal was to provide products that were both elegant and aesthetically pleasing, as well as technically versatile and adaptable.

Winckelmans has been a family business for over 150 years , with five generations succeeding each other. The factory has survived, among other things, the destruction by bombing in 1944, after which it was rebuilt, and the radical shifts in trends that occurred in the early 1980s. This institutional resilience and adaptability have ensured that the production techniques and material composition of the original porcelain stoneware have been preserved.

Winckelmans' current positioning is that of a custodian of critical industrial heritage. The company is the last European manufacturer to offer this specific type of unglazed, fully vitrified product. With a factory in Lille and approximately 120-150 employees, Winckelmans produces approximately 700,000 square meters of tiles annually, 80% of which are destined for the export market.

What is Fully Vitrified Porcelain Stoneware?

Winckelmans mosaic belongs to the category of dry-pressed, unglazed porcelain stoneware tiles. This is a high-quality ceramic composition characterized by the vitrification process. During production, the tiles are pressed under high pressure and then fired at extremely high temperatures. This process creates an extreme density of the particles in the tile mass.

A key feature is the through-the-body coloring (teinté dans la masse) . This means that the dyes and patterns are distributed throughout the entire thickness of the tile mass. This guarantees that even after deep wear from heavy traffic, the color remains intact. This fundamentally distinguishes porcelain stoneware from glazed tiles, where the color is present only in a surface layer.

The Production Process

Winckelmans combines traditional craftsmanship with modern, automated machinery , including investments in robotics and new kilns to increase productivity and quality. This approach to "traditional industrialization" is crucial for ensuring the authenticity of the product, combined with the efficiency and scale required to meet international demand.

The production process includes:

- High pressure pressing: the raw materials are pressed together under extreme pressure

- Vitrification: baking at extremely high temperatures for maximum density

- Through-the-wall coloring: pigments are distributed throughout the mass

- Quality control: each tile is checked for consistency

Exceptional Features

Near-Zero Porosity

The density achieved through vitrification results in extremely low porosity, officially classified as "close to zero." According to European standards, this falls under group B1A, which indicates a water absorption of ≤0.5% (according to EN ISO 10545). The tiles are impermeable to water and most liquids.

Extreme wear resistance

The combination of the through-dyeing and the extreme hardness, verified by the UPEC classification system , ensures exceptional resistance to surface damage and mechanical wear. The color integrity is maintained, even after decades of heavy traffic.

Suitable for All Environments

Winckelmans mosaic tiles are virtually impermeable and suitable for use in all environments: indoors or outdoors, on floors and walls, in wet or dry conditions. The tiles are resistant to freeze-thaw cycles, water, and chemicals.

Natural Matte Finish

Unglazed stoneware is distinguished by its natural, untreated, matte finish . This avoids the "glossy, plastic" sheen often associated with other types of tile. The sharp, flat edges and understated appearance resonate with the authentic aesthetic of historic architecture.

Dimensions and Specifications

Winckelmans' product range includes more than 50 different shapes and sizes , resulting in more than 5000 standard tile designs.

Micro Mosaic 12x12mm

- Tegelgrootte: 12x12mm (½ inch)

- Tile thickness: approximately 4mm (1/6 inch)

- Sheet size: 31x31cm = 484 tiles

- Dekking per m²: 10.4 sheets

- Dekking per 30,5x30,5cm (1 sq ft): circa 1 sheet

- Delivery: on sheets (net on the back) or loose tiles

Other available formats:

- 20x20mm (standard mosaic square, 3.8mm thick)

- 50x50mm (larger mosaic tiles, 5mm or 9mm thick)

- Rectangles, hexagons, octagons, triangles, diamonds, and rounds

Please note: Different thicknesses are available for different applications: 4mm for walls and light floors, 5mm for standard floors, and 9mm for commercial floors with very heavy traffic.

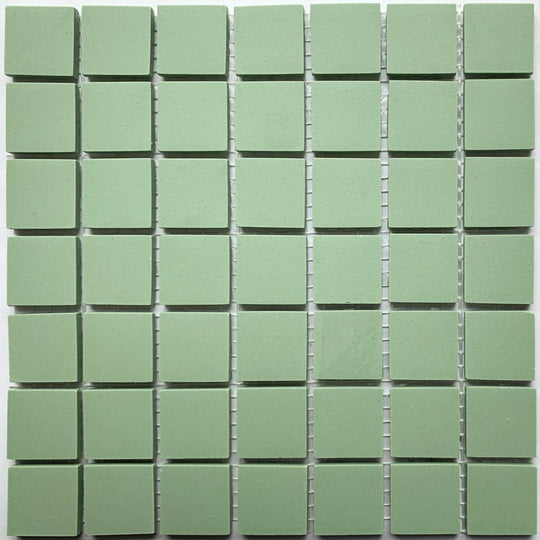

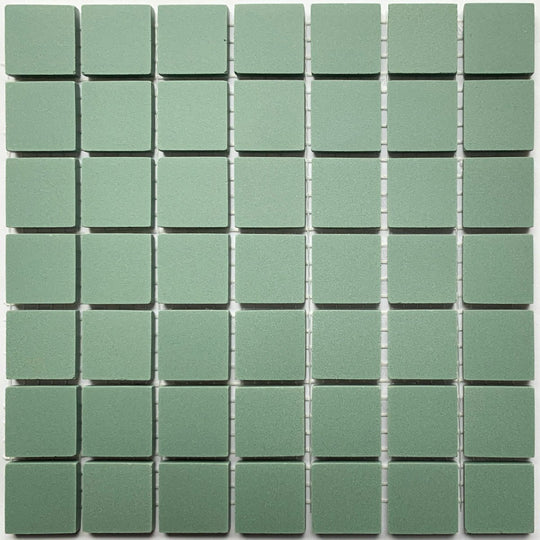

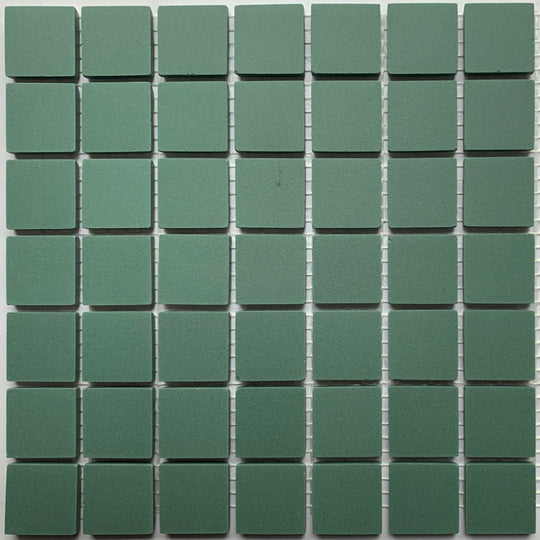

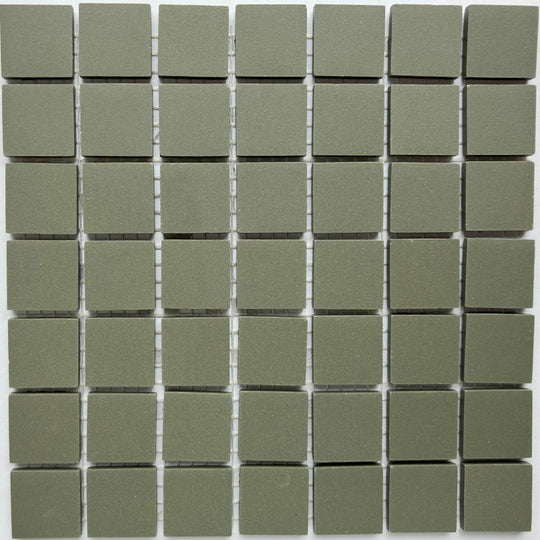

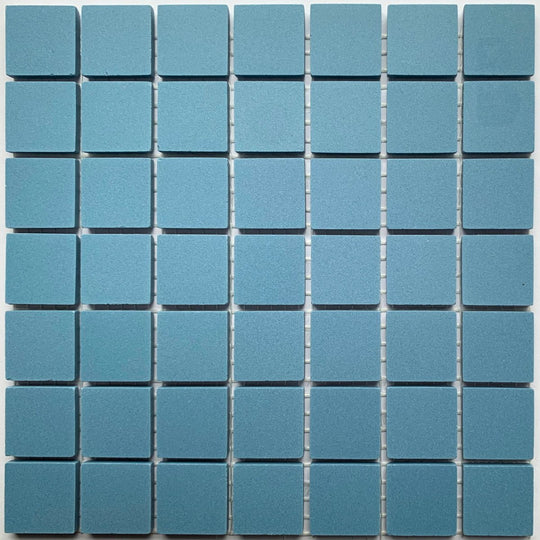

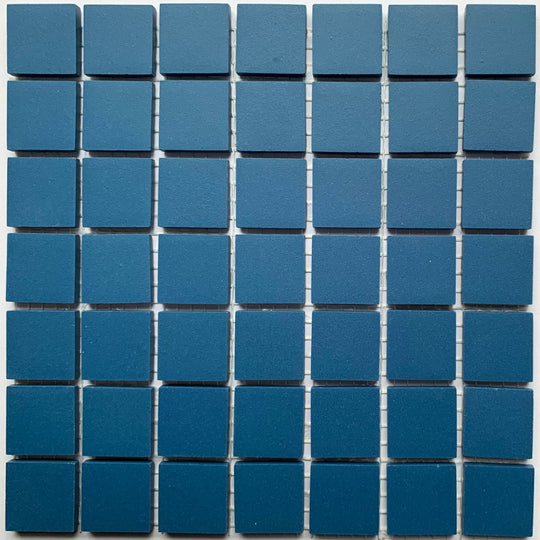

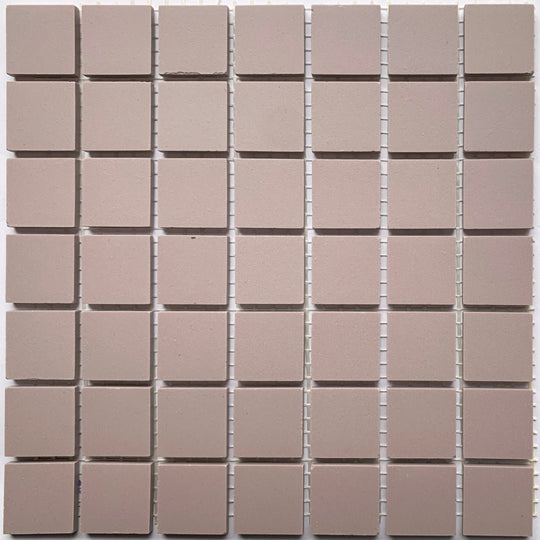

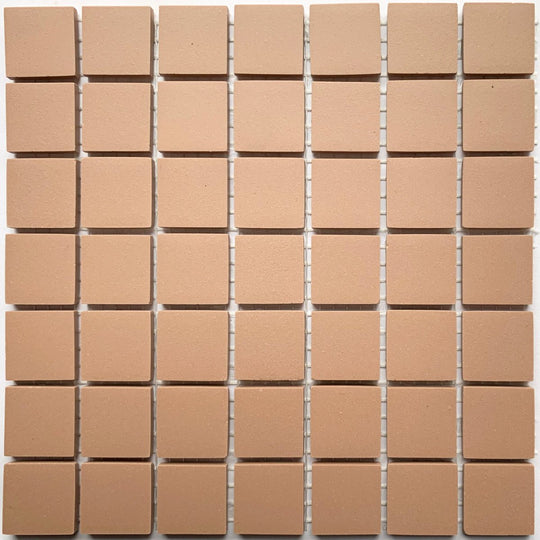

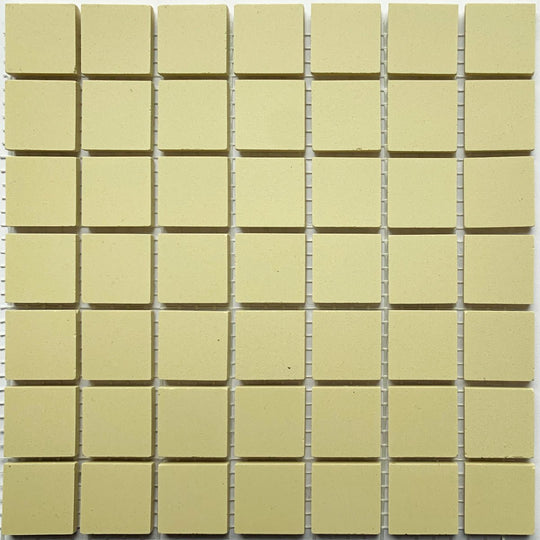

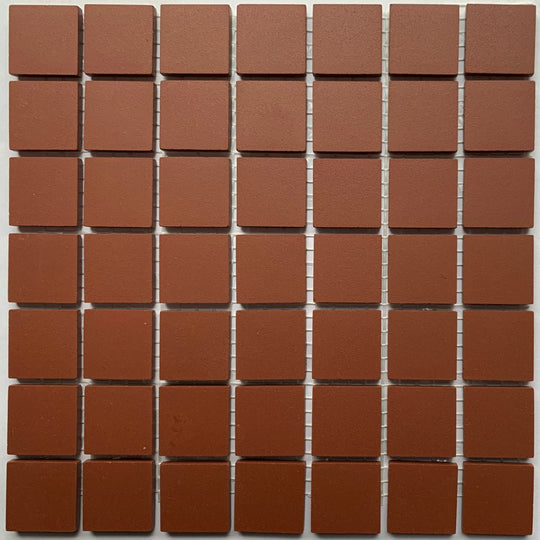

Color palette

Winckelmans works with a palette consisting of 24 basic colours for the geometric series, structured in different typologies:

Solid colors

Consistent, solid shades like Super Blanc (white) and Noir (black) for clean, modern designs.

Porphyry colors

Rich, marbled colours like Green-509 and Rust-506 for a natural, organic look.

Speckled or Mottled colors

A unique range that combines various colored particles in a single tile, such as Pyrenees-PYR and Amazon-Ama. The pickled finish is particularly valuable for heavy-traffic applications because it effectively masks dirt and signs of wear – a historically valued feature that today improves visual hygiene and ease of maintenance in busy public spaces.

Working with Winckelmans Mosaic

Cutting and Tools

Despite the extreme density and hardness of the fully glazed porcelain stoneware, the tiles are known for their relative ease of cutting:

- Standard tile nippers: suitable for most cutting work

- Score-and-snap nipper: for precise, geometric shapes

- Oil-filled glass cutter with crowbar: for the most precise work

Installation and Joint Advice

Important: Use Pigment-Free Grout

A strict guideline for application is the use of pigment-free grout . This is because the unglazed, extremely dense surface reacts differently than porous or glazed materials. Pigments in the grout can accumulate on the microscopic, matte surface and result in unwanted stains or an uneven finish that is difficult to remove.

Installation instructions:

- Preparation: If underfloor heating is used, it must be switched off during the cleaning phase and the floor must be cold and dry.

- Cleaning: Remove joint veil and construction dirt approximately 48 hours after laying, after the joint material has hardened.

- Material requirement: 10-15% allowance recommended to allow for cutting loss

- Glue: use suitable tile adhesive for ceramic tiles

Maintenance and Sealing

One of the greatest advantages of fully vitrified porcelain stoneware is its minimal maintenance requirements . Thanks to their near-zero porosity, the tiles are impermeable and retain their appearance for decades without the need for sealing or caulking .

Optional impregnation: Although sealing is not required for technical protection, impregnation can be applied optionally if maximum protection against dirt and moisture is desired (for example, with HMK S234 Stain Stop). When using impregnating agents, it is vital that they are applied thinly and any excess product is immediately wiped away with a clean, lint-free cloth.

Daily maintenance:

- Clean with neutral soap and water

- Avoid harsh chemicals

- No sealer needed

- Resistant to all normal cleaning agents

Applications of Winckelmans

The UPEC certification and extreme properties make Winckelmans universally applicable:

- Commercial floors with heavy traffic: shops, hotels, restaurants, offices

- Public spaces: Metro stations (Parisian Metro style), airports, museums

- Wet areas: bathrooms, swimming pools (such as Helperbad in Groningen), spas

- Outdoor applications: terraces, entrances, facades

- Residential: kitchens, bathrooms, hallways, entrances

- Historical restorations: reproduction of original floor patterns and encaustic tilework

- Custom projects: logos, specific drawings and complex patterns

Sustainability and Environment

Sustainability is an integral part of Winckelmans' production ethos:

- Minimal environmental impact: sustainable materials and energy-efficient production

- Virtually no waste: the production process generates almost no waste

- Fully recyclable: the tiles can be recycled at the end of their life cycle

- Long life: decades of use without loss of quality

- No maintenance products needed: no sealers or special cleaning agents required

Customization and Reproduction

Winckelmans excels in custom work and restoration. By combining traditional manufacturing processes with modern computer technologies , the company is able to accurately reproduce existing patterns:

- Reproduction of historical floor patterns

- Custom logos and drawings

- Complex geometric designs

- Color matching for restoration projects

- Combination of different shapes and sizes

UPEC Classification

Winckelmans mosaics are classified using the UPEC rating system , which assesses the suitability of the tiles for different usage environments based on four criteria:

- U (Usure): Wear - resistance to mechanical wear

- P (Poinçonnement): Heavy traffic - resistance to heavy loads

- E (Eau): Water - resistance to moisture and water

- C (Chimique): Chemical resistance - resistance to chemicals

This classification is crucial for architectural selection as it confirms suitability for heavy-duty, commercial and public applications.

Frequently Asked Questions

What does "colored through and through" mean?

At Winckelmans, the dyes are distributed throughout the entire thickness of the tile (teinté dans la masse). This means that even with heavy wear, the color remains intact – the tile looks the same inside as it does outside. This is fundamentally different from glazed tiles, where only the surface is colored.

Do I need to seal Winckelmans tiles?

No, that's not necessary . Due to their near-zero porosity (≤0.5% water absorption), the tiles are naturally impermeable. Sealing is optional and only recommended if you want extra stain protection in very specific circumstances.

Can I use Winckelmans in a swimming pool?

Absolutely! Winckelmans is ideal for swimming pools and other wet areas. The material is impermeable to water, resistant to chlorine and chemicals, and retains its color. Large projects like the Helperbad swimming pool in Groningen have been built using Winckelmans.

Are the tiles suitable for underfloor heating?

Yes, Winckelmans mosaic is compatible with underfloor heating . Please note: turn off the underfloor heating during the cleaning phase after installation and ensure the floor is cool and dry before cleaning.

Why can't I use pigmented grout?

The unglazed, matte surface of Winckelmans reacts differently than glazed tiles. Pigments can accumulate in the microscopic surface and cause unwanted stains that are difficult to remove. Always use unpigmented grout.

Can I have historical patterns reproduced?

Yes! Winckelmans combines traditional manufacturing with modern computer technology to accurately reproduce existing patterns, logos, and specific designs. This makes it ideal for restoring historic floors and encaustic tilework.